Trusted ERP Solutions Provider To Small, Medium and Large Enterprises

How ERP (Enterprise Resource Planning) for Trading Enhances Supplier Order Management and Procurement Management

Enterprise Resource Planning (ERP) systems have become the backbone of modern trading businesses, streamlining operations across order processing, procurement, and inventory management. In fast-paced trading environments, efficient order fulfillment and supplier coordination are critical—and ERP solutions deliver these with automation, integration, and real-time data flow.

I hope you find this blog post insightful. If you’d like our team to handle technology in your business and bring the best ROI, click here.

What is ERP (Enterprise Resource Planning) in Procurement Management?

ERP (Enterprise Resource Planning) is like having a digital manager for your trading business. It makes sure you don’t forget to order stuff, checks how much you have left, reminds you when to restock, and even finds out if your suppliers are late delivering things. In procurement, this system makes sure businesses always have what they need, whether it’s raw materials, tools, or finished goods.

A huge part of this is supplier order management — keeping track of all the orders you’ve placed with suppliers, when they’ll arrive, how much they cost, and whether the delivery is complete and on time. Think of it like this — without ERP, managing orders is like juggling balls blindfolded. You might drop one or miss another. But with ERP and proper supplier order management tools, it’s like having a smart assistant that sees everything, reminds you what to do, and even warns you if something’s about to go wrong.

Trading businesses use ERP to:

Order Management

Keep inventory records

Manage supplier order management tasks

Pay suppliers on time

Compare vendor deals

Maintain real-time data

So, ERP (Enterprise Resource Planning) in procurement management is like having a super organizer who keeps the business neat, smart, and ahead of problems, making supplier order management a breeze.

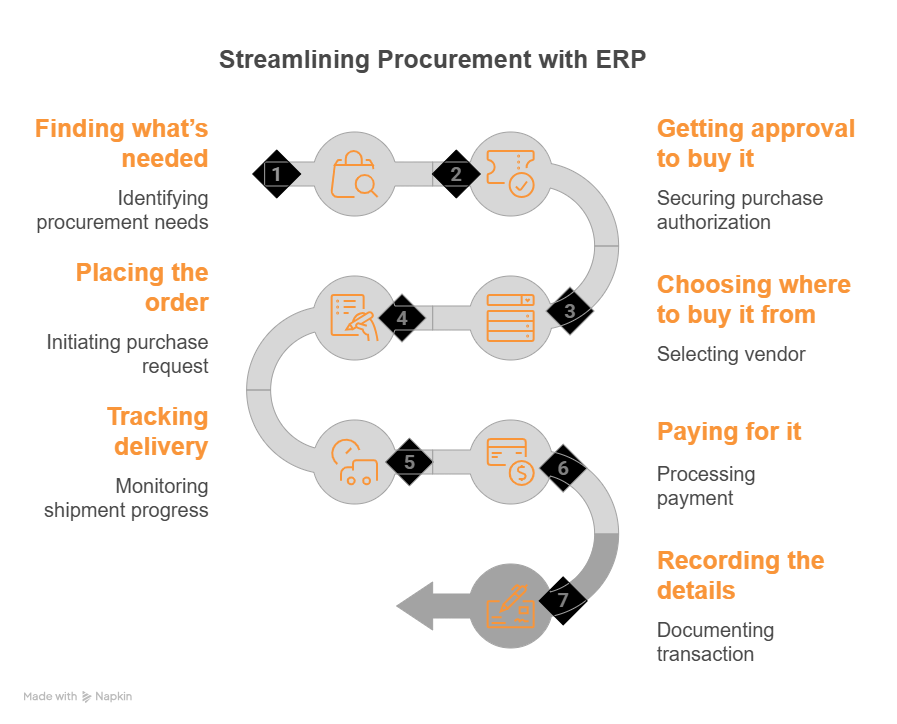

Which Procurement Steps Can ERP (Enterprise Resource Planning) Help Streamline?

Now, you might wonder — how exactly does ERP (Enterprise Resource Planning) help in the step-by-step process of buying things? Let’s break it down like a recipe. When a business wants to buy something, here’s what typically happens:

Finding what’s needed

Getting approval to buy it

Choosing where to buy it from

Placing the order

Tracking delivery

Paying for it

Recording the details

Without a good system, this can get messy. But ERP makes each of these steps quicker, clearer, and smarter — especially when it comes to supplier order management. Here’s how:

Needs Identification: ERP shows what’s low in stock by checking real-time inventory.

Approval Management: It automatically sends a request to the manager for approval.

Supplier Selection: It keeps a list of trusted suppliers with price details, so picking one is easy.

Order Management: ERP sends the order and tracks its status, so no more lost emails!

Delivery Tracking: It checks delivery times and alerts if something’s delayed, improving supplier order management reliability.

Payment Processing: It handles invoices and pays on time.

Records Management: It saves everything orders, receipts, payments, and supplier histories, just in one place.

This way, what used to be a headache of paperwork, phone calls, and manual mistakes is now handled like clockwork by a smart system with sharp supplier order management tools.

ERP (Enterprise Resource Planning) for Order Management in Trading Business

Order management within an ERP system covers the full lifecycle from customer order capture to shipment and invoicing. ERP platforms ensure:

Real-time order validation against stock levels

Automatic creation of pick lists and delivery notes

Status tracking from warehouse to delivery

Seamless integration with billing and finance modules

Example: When a sales order is created, ERP checks inventory, reserves stock, and schedules dispatch—all without manual intervention.

Benefits of Using Trading ERP (Enterprise Resource Planning) for Procurement Management

So, why do businesses love ERP (Enterprise Resource Planning) systems for procurement management? Because it turns a slow, confusing job into a smooth, easy one. Think about it like upgrading from a regular bike to an electric one — everything gets faster, easier, and more fun.

Here are the top benefits:

Saves Time: No more wasting hours on spreadsheets or chasing suppliers. ERP handles most tasks automatically.

Prevents Mistakes: It warns you if you’re about to double-order or buy from the wrong supplier.

Keeps Everything Organized: All order, supplier, and inventory information — including supplier order management data — is neatly stored in one place.

Improves Decision Making: With real-time data, you always know what’s going on — like having a live scoreboard.

Helps Stay on Budget: You can track spending instantly and avoid unnecessary purchases.

Imagine your school library. If every book was scattered and no one knew what was missing, it’d be chaos. But with a smart computer system listing what’s available, what’s checked out, and what’s overdue — it runs smoothly. ERP does the same for procurement. It makes supplier order management easy, automatic, and foolproof.

In short, ERP makes businesses smarter and more organized, saves money, prevents mistakes that cost time and reputation, and takes the hassle out of managing supplier orders.

7 Ways ERP (Enterprise Resource Planning) Enhances Strategic Procurement Operations

Now let’s dive into the cool part — how ERP makes procurement not just easier, but smarter and way more strategic. It’s like going from a paper map to GPS with traffic updates. Here are 7 powerful ways ERP (Enterprise Resource Planning) can level up your procurement game — especially when it comes to handling supplier order management.

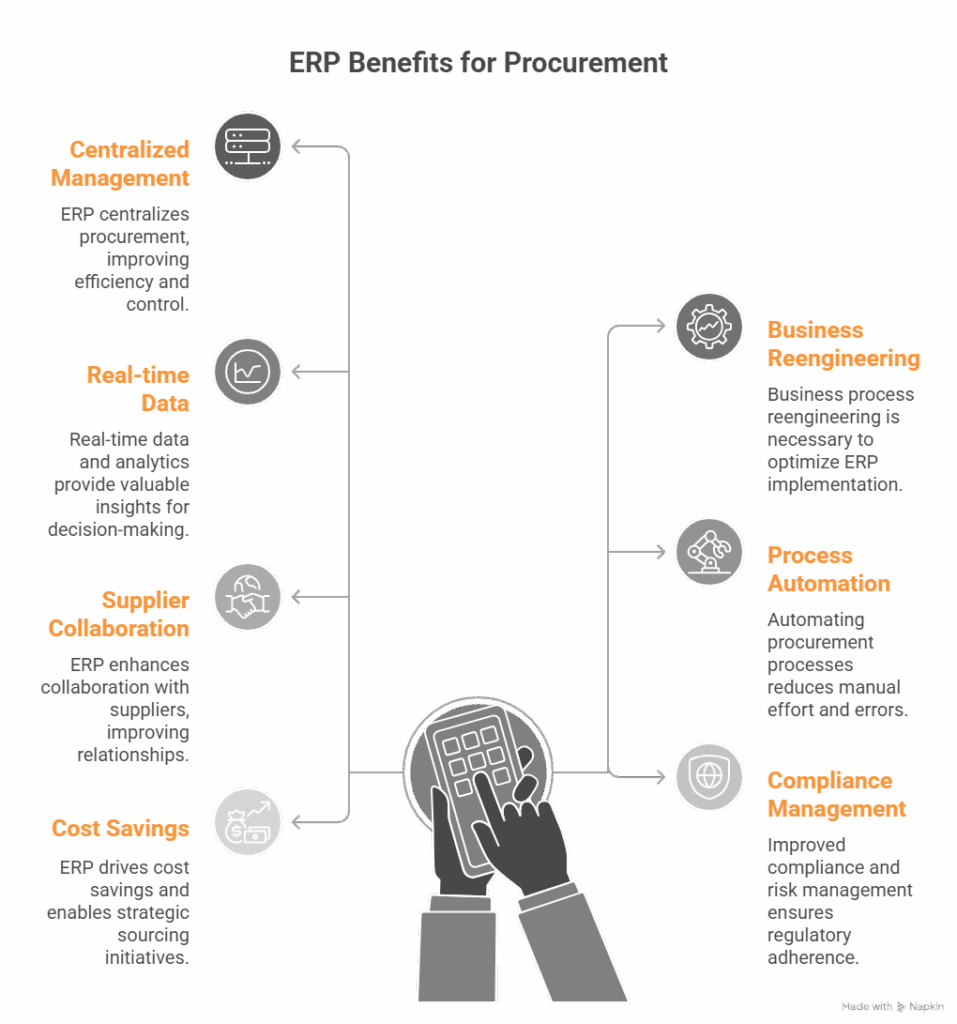

1. Centralized Procurement Management with ERP

ERP (Enterprise Resource Planning) keeps all procurement activities, orders, and supplier information in one smart, central system. Before this, different departments might have used their own spreadsheets, emails, or even sticky notes. That’s a recipe for mistakes! But with ERP:

Everyone sees the same information in real time.

No more duplicate orders or missed items.

Supplier order management is clear, organized, and trackable.

It’s like turning a messy, noisy classroom into a neat, well-organized one where everyone knows the plan. You always know which supplier was given which order, the delivery status, and what’s pending.

2. Necessity of Business Process Reengineering (BPR)

Sometimes, businesses follow old, slow processes just because that’s how it’s always been done. ERP encourages companies to rethink those outdated routines and replace them with smarter, faster ones. It’s like switching from walking to using a bike — faster, smoother, and much more fun.

With ERP:

Unnecessary steps are removed.

Boring, repetitive jobs like manual supplier order management get automated.

People can spend more time finding better suppliers and negotiating deals.

It forces businesses to modernize — making sure supplier relationships and orders are handled faster, cleaner, and without the old mess-ups.

3. Leveraging Real-time Data and Analytics

One of the best things about ERP is how it gives live updates on everything — stock levels, order statuses, supplier performance, and prices. It’s like having a weather app that instantly tells you if it’s about to rain, instead of guessing.

When it comes to supplier order management, this is a total game-changer. With ERP:

You can see if a supplier’s order is late before it becomes a problem.

Know instantly what’s in stock, what’s ordered, and what’s missing.

Spot suppliers that consistently underperform and replace them before they cause bigger issues.

ERP reports and dashboards turn piles of boring numbers into easy-to-read, real-time insights. This lets procurement management teamsanagement teams make smarter, faster decisions that keep everything running smoothly

4. Automating Procurement Processes

Now here’s where ERP starts to feel like having your very own robot assistant. It can automate procurement management tasks, handling boring, repetitive jobs on its own. That includes a huge part of supplier order management.

With ERP automation:

It reorders supplies when stock runs low.

Sends purchase requests to managers.

Automatically generates and sends purchase orders to suppliers.

Tracks deliveries and logs them.

Processes supplier invoices without human error.

Think of it like a robot that places your favorite snack order when your stash runs out — only it’s for your entire business. This means:

Fewer mistakes and delays.

Faster, reliable supplier order management.

More time for your team to handle important things like getting better deals or planning smarter.

Automation means everything moves smoothly, orders get placed on time, and suppliers stay happy.

5. Enhancing Supplier Collaboration

Good relationships with suppliers are the secret weapon of any successful trading business. Think about it — if your suppliers like working with you because you’re organized, fair, and fast to respond, they’re more likely to give you better deals, faster service, and priority during busy times. This is where ERP makes a huge difference, especially in supplier order management.

An ERP system improves supplier collaboration by:

Keeping all communication clear and documented — no more digging through old emails.

Sharing order updates, changes, and delivery schedules in real time.

Providing fast, honest feedback on supplier performance.

Making faster, reliable payments without delays.

It’s like having a well-organized group chat where everyone’s on the same page. No more “he said, she said” situations. And because everything is logged inside the ERP, businesses can track supplier performance, see who’s reliable, and reward or replace them based on solid facts.

Supplier order management inside an ERP (Enterprise Resource Planning) system means smoother conversations, better planning, and fewer arguments. Suppliers love working with businesses that know what they’re doing, and ERP helps you be one of them.

6. Improved Compliance and Risk Management

Running a business means following rules — and breaking them, even by accident, can cause huge problems. From contract terms to payment deadlines, everything has to be done by the book. That’s why ERP systems are so useful. They make sure everything in procurement is properly recorded, legal, and risk-free — including supplier order management.

Here’s how (Enterprise Resource Planning) improves compliance in Trading Business:

Tracks all supplier orders automatically

Ensures contracts and orders match legal requirements

Alerts you if something is missing, overdue, or looks unusual

Keeps everything transparent and easy for audits

When it comes to risk, ERP is like having a built-in safety net. It can quickly flag problems, like a supplier consistently delivering late or prices rising unexpectedly. With real-time data from the ERP, businesses can act fast, adjust their orders, or look for other suppliers before issues grow.

Having smart, automated supplier order management means nothing falls through the cracks. It protects the business, keeps suppliers in check, and avoids problems with paperwork, deadlines, or missing records.

7. Cost Savings and Strategic Sourcing

Now, here’s the really fun part — saving money while getting better quality. ERP systems track prices, supplier performance, and order history, making it super easy for businesses to shop smarter and negotiate better. That’s where supplier order management comes in again.

ERP makes it easy to:

Compare prices between different suppliers

Track spending habits and spot waste

Identify cheaper, more reliable suppliers

Avoid unnecessary stockpiling or last-minute buying at high prices

It’s like having an online shopping app that automatically compares prices, rates sellers, and tracks your past orders. Businesses can see which suppliers consistently offer the best deals and which ones are costing them money.

With this data, companies can start strategic sourcing — which means choosing suppliers not just by price but by value, reliability, and long-term benefits. ERP transforms procurement from a routine chore into a smart, money-saving operation.

By mastering supplier order management with ERP, companies stay ahead of their competitors, reduce waste, avoid surprises, and build a better, more profitable supply chain.

Challenges of ERP (Enterprise Resource Planning) for Procurement

ERP systems are awesome, but they’re not magic wands. Like anything powerful, they come with some challenges. If a business isn’t ready, ERP can feel more like a headache than a help especially when setting up supplier order management for the first time.

Here are the most common bumps in the road:

Big Setup Costs: Good ERP software isn’t cheap. There’s licensing, training, maybe even new hardware. It’s an investment.

Complex Implementation: It takes time to roll out an ERP system. You need to train your team, clean up old data, and set up workflows.

Resistance to Change: Some employees are used to the old way — spreadsheets and email chains. Adapting to ERP might scare them at first.

Customization Trouble: Every business is different, and not all ERPs fit like a glove out of the box. Customizing features like supplier order management might take extra effort.

Data Migration Risks: Moving info from old systems to the new ERP can go wrong if not done carefully — especially when dealing with thousands of supplier records.

But here’s the bright side — once it’s up and running, ERP becomes a total game-changer. Most companies say the long-term value — smoother operations, better supplier management, faster buying cycles — makes every challenge worth it.

Leveraging Procurement Technology with ERPs

ERP is great on its own. But when you combine it with other smart tools? It becomes a procurement powerhouse. Think of it like adding nitro to a race car.

Here are some tech tools that make ERP even better:

E-Procurement Platforms: These online tools integrate with ERP and make placing orders, getting approvals, and processing payments faster and paperless.

Supplier Relationship Management (SRM) Systems: These focus just on suppliers — helping you manage contracts, rate their performance, and improve supplier order management.

Mobile Apps: With mobile-friendly ERP tools, you can check orders, approve purchases, and view supplier updates on the go.

Cloud Technology: Cloud-based ERPs are easy to scale, update, and access from anywhere — perfect for fast-moving businesses.

AI and Analytics: Some ERPs include smart tools that predict demand, spot savings, and suggest better sourcing decisions.

When combined, these tools give procurement teams superpowers. They work faster, make better choices, and build rock-solid supplier relationships with smarter supplier order management.

ERP System VS Procurement ERP Tools

Feature/Functionality | Trading Business ERP System | Standalone Procurement Management Tool |

Integration | Fully integrated with inventory, sales, finance, and CRM | Operates independently; may require custom integrations |

Data Consistency | Single data source across all modules | May result in data silos or duplication |

Workflow Automation | End-to-end automation from requisition to payment | Limited to procurement processes |

User Interface | Unified dashboard for multiple departments | Procurement-focused interface only |

Analytics & Reporting | Cross-functional reports with real-time data | Focused on procurement metrics only |

Vendor Management | Includes vendor evaluation, contracts, and compliance | Basic supplier directory and purchase tracking |

Approval Workflows | Role-based, configurable for multiple departments | Usually limited to procurement chain |

Scalability | Scales with business size and complexity | May require switch to ERP as business grows |

Cost Efficiency | Higher upfront cost, but better long-term ROI | Lower cost initially, limited scalability |

Maintenance | Centralized updates and support | May require separate support for integrations |

Best ERP (Enterprise Resource Planning) Systems Used in Trading

Some of the most popular ERP systems for trading businesses include:

SAP Business One

Oracle NetSuite

Microsoft Dynamics 365

Odoo ERP

TallyPrime with ERP modules

ZOHO

These platforms offer customizable modules tailored to trading workflows.

Case Study: BrightTrade Supplies Gets Smarter with ERP

Let’s bring this to life with a real-world example. Meet BrightTrade Supplies, a mid-size trading company dealing with hundreds of suppliers across the country.

The Problem:

Bright Trade was buried in paper-based procurement. Orders got lost, deliveries were late, and payments were often delayed. They had no clear system for supplier order management, and the chaos was hurting their business.

What They Did:

They installed a cloud-based ERP system with built-in procurement modules. It automated orders, tracked deliveries, and provided a centralized dashboard for supplier order management.

The Results:

Order errors dropped by 80%

Late deliveries were reduced by half

They saved 25% on procurement costs in the first year

Supplier satisfaction went up thanks to timely payments and clear communication

Now, Bright Trade knows exactly what’s been ordered, what’s arriving, and which suppliers are performing best — all in one easy-to-read dashboard. They finally have control, and they’re not going back to their old ways.

Frequently Asked Questions (FAQs)

It’s the process of tracking, managing, and organizing all orders placed with suppliers, from the moment an order is created to its delivery and payment.

Yes. Many cloud-based ERP systems are designed specifically for small and medium-sized companies, offering affordable plans and easy setups.

Yes. Cloud-based ERP providers use advanced security technologies, encrypted connections, and regular data backups to keep business data safe.

Cloud-based ERP systems can often be set up within a few days, while on-premise systems may take weeks or months to install and configure.

ERP helps automate, organize, and speed up all the steps in procurement, from choosing suppliers to paying invoices — making the whole process smarter and more reliable.

It depends on the company size and needs. Some take a few months, others might need a year for full setup and training.

No! Small and medium businesses benefit too. There are many ERP options scaled for different company sizes and budgets.

Yes! Through better supplier order management, fewer mistakes, and smarter sourcing, ERP systems often cut procurement costs by 20-30%

Saeeda Riaz

Partner at AGN IT Services LLC | Strategic IT Partner of 10+ Enterprises

Saeeda Riaz is a seasoned IT consultant with over 23 years of experience in delivering innovative technology solutions to businesses across various industries. As the driving force behind a leading IT solutions company, she specializes in digital transformation, business automation, and software development. Her strategic vision and hands-on expertise help organizations streamline operations, enhance efficiency, and stay ahead in the digital landscape.

Connect on LinkedInContact us for IT Solutions